As we all know ,there are many types conveyor or feeding device for packing machine.

Today I’d like to introduce landpack conveyor for feeding product automatically .

For granule product feeding ,there Z type conveyor ,slop type conveyor ,slope type elevator ,bowl hopper conveyor ,

First is the Z type conveyor

This type conveyor was used in regular product transportation,easy crash product ,such as sugar ,hardware,nut,chip

salt,bean,etc.......whole set product with 304 stainless steel material,(carbon steel as option),easy to clean and disassemble ,food grade PP material to touch with product ,most used in food product ,storage hopper is 20L and 40L as option ,conveyor hopper 5L ,

Independent operation panel,work stable and low noise,height can be customize ,

Second slope elevator

This type conveyor is mainly used in bulk ,grain,frozen product,and finished product conveyor

The height ,belt width and length and speed all can be customize,simple structure ,easy to install.

Economical ,wide range application,easy to celan when

Third bowl hopper conveyor .

This conveyor was consist of by many bowl hopper ,it used used in some product with liquid ,or some granule with powder,avoid the liquid or powder overflow,but it requests your product was measured already ,doesn’t need to dose any more .workers just put product inside the bowl ,then to feed automatically.

Powder product feeding

First is the screw auger conveyor ,as below

There are many types screw auger conveyor to choose according to your capacity production and packing requirements ,all material is 304 stainless steel never rust ,

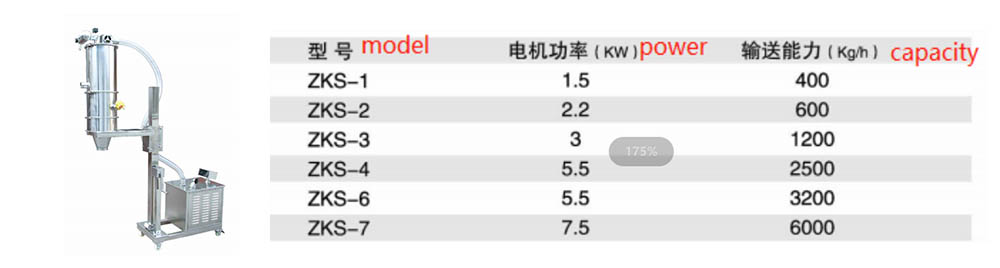

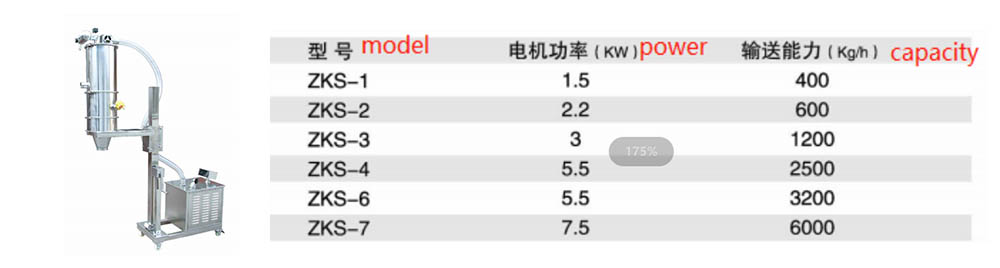

Second is the vacuum feeding machine

This product was used in many kinds of powder ,because it is very easy to disassemble to clean ,save space ,especially if your warehouse height is limited ,this is best choice .

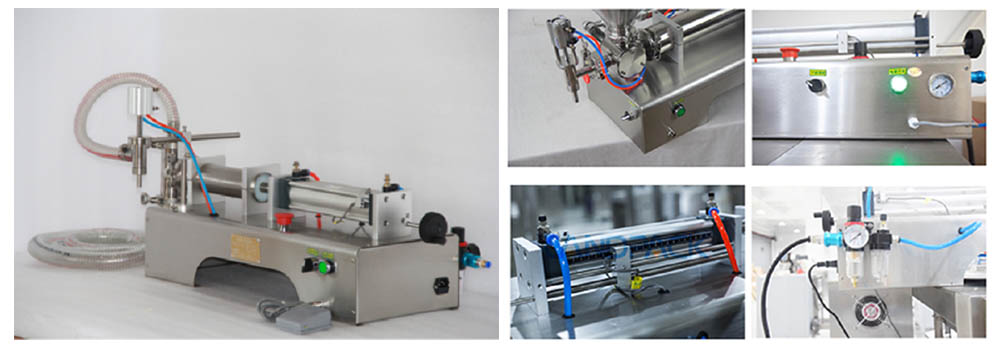

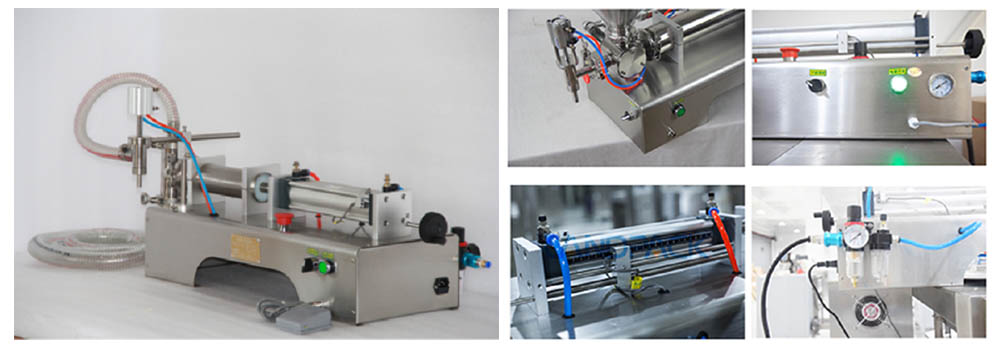

Liquid feeding product we use pump to feed product ,there are many kinds of pump to feed liquid ,such as piston pump,clean, sanitary pump,rotor pump,today I will introduce our piston pump to everyone as reference .

Piston pump as below

It’s consist of below part

1. Every corner of the machine shows the meticulousness of the processors.

2. Anodic oxidation of a small piece of material with angle grinding and edge grinding

3.Aluminum oxide stainless steel screws are used to fasten the machine structure to prevent rusting.

Feature:

1.Single-end filling

304 stainless steel, can choose filling paste or filling liquid, meet GMP requirements, and no dead angle, easy to clean.

2.Pneumatic control

The filling accuracy can be controlled at <0.5% by using compressed air control and mechanical position control.

3.Digital adjust

The filling capacity is regulated by the calibrated screw, so that the filling capacity is regulated accurately.

4.304 stainless steel

304 stainless steel fuselage is used in this machine, and 304 stainless steel is used in the material contact part.

5. Safety and practicability

This product is suitable for use in explosion-proof requirements and humid environment with high safety.

Above are just LANDPACK some conveyor ,there are also many other conveyor can customize ,today I’d like to share some common conveyor for customer to reference.

If you product is special and have high requirements on the machine ,just contact us for more advice ,landpack engineer will provide the most suitable solution for you !

Thanks for your watching !see you next time